ハンバーガー表示用 削除しないでください

What is copper foil?

Copper foil is a thin sheet of copper with a thickness in microns(µ).

Imagine a copper version of aluminum foil or gold leaf. A sheet made of thin copper is called copper foil.

Copper foil is used in a variety of fields, including electronic devices such as smartphones and computers, home appliances, automobiles, and construction, and is one of the important materials that support your daily life.

※µm = 1/1,000,000m

Copper foil is used in a variety of fields, including electronic devices such as smartphones and computers, home appliances, automobiles, and construction, and is one of the important materials that support your daily life.

※µm = 1/1,000,000m

Types of copper foil

There are two types of copper foil, electro-deposited copper foil and rolled copper foil, each with different characteristics and used for different purposes.

Mitsui Kinzoku's Copper Foil Division specializes in electro-deposited copper foil and has begun efforts to find new possibilities in addition to the main application of printed wiring boards.

※Printed wiring board: A substrate to which electronic components are attached and to which electrical connections between components are made.

An electric circuit is formed by the combination of copper foil and substrate.

Mitsui Kinzoku's Copper Foil Division specializes in electro-deposited copper foil and has begun efforts to find new possibilities in addition to the main application of printed wiring boards.

※Printed wiring board: A substrate to which electronic components are attached and to which electrical connections between components are made.

An electric circuit is formed by the combination of copper foil and substrate.

Copper foil manufacturing process

Electrolytic copper foil and rolled copper foil are made in different ways: electrolytic copper foil is made by electrolytic copper plating, while rolled copper foil is made by pressing copper ingots and stretching them thin. (We are a manufacturer specializing in electro-deposited copper foil. We do not handle rolled copper foil.)

manufacturing process for

electrodeposited copper foil

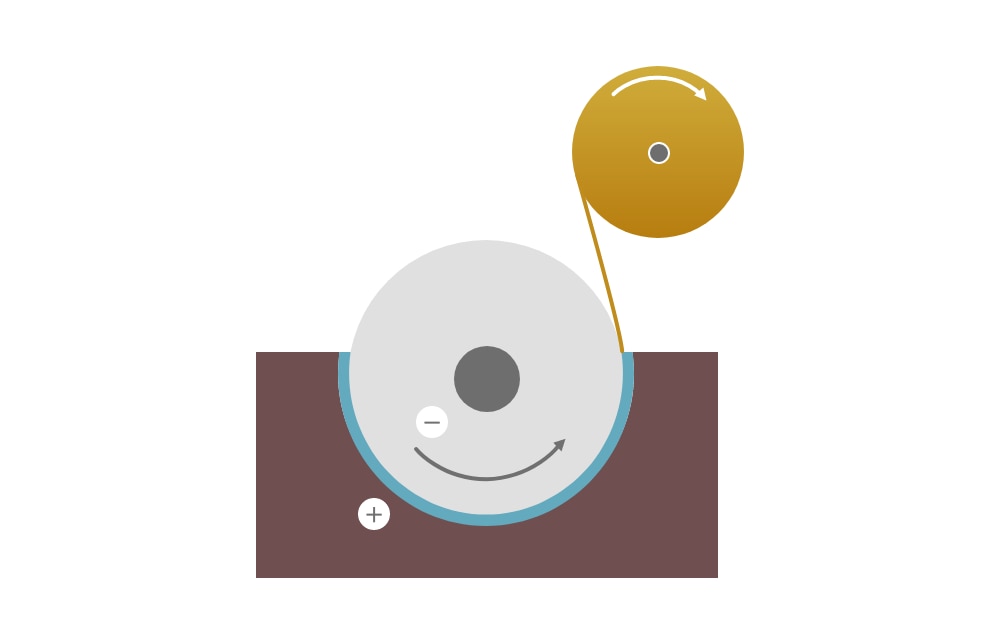

Electrolytic copper foil is produced by electrolytic copper plating. When a cathode drum is immersed in copper sulfate electrolyte and electricity is passed from the anode to the cathode, copper is deposited on the drum surface.

Because copper is deposited by plating, the process is good at producing thin foils.

Mitsui Kinzoku manufactures electro-deposited copper foil using 100% recycled raw materials.

Because copper is deposited by plating, the process is good at producing thin foils.

Mitsui Kinzoku manufactures electro-deposited copper foil using 100% recycled raw materials.

Manufacturing process for

rolled copper foil

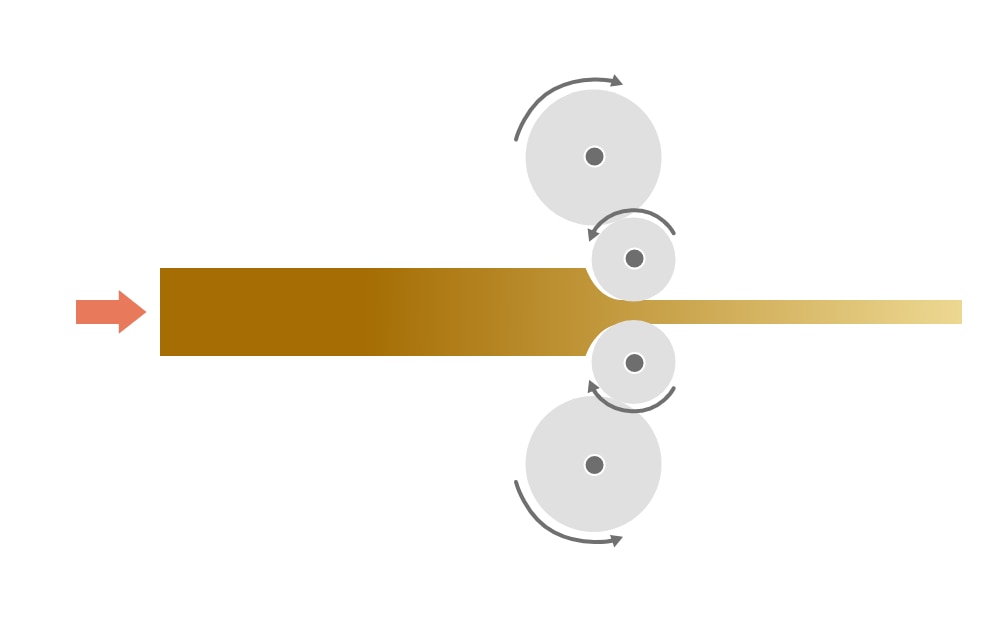

Rolled copper foil is manufactured by pressing and stretching copper with a rotating roll to make it thin to the desired thickness. Because it is made by crushing copper, rolled copper foil is good at producing copper foil with a certain thickness.

Features of Copper

| 01 | Features |

Good conductivity

A comparison of conductivity, a measure of the ease with which electricity flows, shows that copper has the second highest conductivity after silver. Because of its ease of electricity flow, copper is used as a printed wiring board in many electronic devices such as PCs, TVs, and game consoles.

| Metal | conductivity(%)* |

|---|---|

| Silver | 105.4 |

| Copper | 100.0 |

| Gold | 75.6 |

| Aluminum | 62.0 |

| Iron | 17.4 |

From National Astronomical Observatory of Japan, Chronological Table of Science, Vol. 65 (Maruzen Co., Ltd., 1992)

*The conductivity of copper (volume resistivity 1.55 x 10-8 Ω・m) at 0°C is shown as 100%.

|

Metal |

Thermal conductivity[W/(m・K)]* |

|---|---|

| Silver | 428 |

| Copper | 403 |

| Gold | 319 |

| Aluminum | 236 |

| Iron | 83.5 |

From National Astronomical Observatory of Japan, Chronological Table of Science, Vol. 65 (Maruzen Co., Ltd., 1992)

*This indicates the thermal conductivity at 0°C.

| 02 | Features |

Good thermal conductivity

A comparison of thermal conductivity, a measure of how easily heat is transferred, shows that copper has the second highest thermal conductivity after silver. Because it conducts heat so easily, copper is used in heat exchangers, air conditioners, and pots and pans.

| 03 | Features |

Good workability

Copper can be reshaped by chemical etching or drilling. Electrolytic copper plating can also be used to form microscopic bumps. The size of the bumps can be adjusted to the desired size by changing the processing conditions. (See figure).

Mitsui Kinzoku's Technologies

Mitsui Kinzoku has excellent technologies to add various functions to electrodeposited copper foil.

Why don't you look for new possibilities in combination with those technologies?

Why don't you look for new possibilities in combination with those technologies?

Contact Us

Learn more about

Copper Foil Division Technical Handbook!

Copper Foil Division Technical Handbook!

Could we do something like this?

If you think so, please feel free to contact us!

If you think so, please feel free to contact us!

English

繁體

簡体