Leading Company

of 3D Printing Copper

High Conductivity ×

Printability

Printability

Mitsui Kinzoku, a leading Japanese inorganic material manufacturer,

provides spherical copper powders made by gas atomize that are ideal for use with various 3D printers.

provides spherical copper powders made by gas atomize that are ideal for use with various 3D printers.

Cost Effective, High Performance for Aerospace and Defence

The MA-CCR25H, a next-generation copper material surpassing GRCop-42, is specifically designed for the aerospace industry. This material is ideal for rocket parts, particularly rocket engines and chambers. The MA-CCR25H demonstrates comparable strength and thermal conductivity to commercial copper alloys while exhibiting lower manufacturing costs. Users can choose the most suitable annealing profiles based on their designs.

Advantage of MA-CCR25H compared to Commercial Copper Alloys

| Material | Post Heating | Performance of Printed Parts | Manufacturing Cost Related Factors | |||||

| Tensile Strength at R.T. /MPa |

Tensile Strength at 400℃/MPa |

Thermal Conductivity W/mK |

Material Cost | Printing Productivity cc/h |

||||

| Vertical | Horizontal | Vertical | Horizontal | |||||

|

CuCr |

Anneal at 600℃ | 404 | 482 | 187 | 222 | 298 | $ Inexpensive |

✓✓ High |

| Anneal at 650℃ | 356 | 393 | 169 | 178 | 330 | |||

| Anneal at 700℃ | 282 | 344 | 139 | 150 | 343 | |||

| GRCop-42 | HIP | 355※1 | 180※1 | 270※1 | $$$ Expensive |

✓✓ High |

||

| HIP at 954℃ | 389※2 | - | 323※2 | |||||

| CuCrZr | Anneal at 950℃, water quenching, aging 600℃ |

295※3 | 340※3 | - | - | 324※4 | $ Inexpensive |

✓ Low |

※1 NASA

※2 Velo3D

※3 Nikon SLM Solutions

※4 Sandvik

※2 Velo3D

※3 Nikon SLM Solutions

※4 Sandvik

FREE SAMPLES NOW

Enhance Cooling Efficiency with Liquid Cooling Solutions for AI Data Centers

Mitsui's additive manufacturing copper solution is a game-changer in thermal management, delivering superior cooling performance ideal for cold plates that provide direct to chip cooling in AI data centers.

It not only ensures a consistently comfortable operating condition but also reduces energy consumption, leading to significant cost savings.

It not only ensures a consistently comfortable operating condition but also reduces energy consumption, leading to significant cost savings.

Comparison Chart for Thermal Management Applications

| Material | Company | Laser Output | Relative Density | Conductivity | Resolution | ||

| Thermal Conductivity |

Electrical Conductivity |

Minimal Wall thickness |

|||||

| W | % | W/mK | % IACS | μm | |||

| CuCr MA-CCR25L |

Mitsui Kinzoku | 400 | 99.5 | 377 | 95 | 200※2 | |

| CuCr MA-CCR25H |

Mitsui Kinzoku | 400 | 99.5 | 349 | 93 | below 150※2 | |

| CuCrZr | EOS※1 | 1000 | 99 | - | 80-85 | - | |

| Sandvik※1 | - | 98 | 324 | 80-90 | - | ||

| Pure Copper | EOS※1 | 400 | 95 | - | 90 | - | |

| EOS※1 | 1000 | 99.6 | - | 100.7 | 700 | ||

※1 Each Company’s website

※2 Mitsui’s internal test result with EOS M290

※2 Mitsui’s internal test result with EOS M290

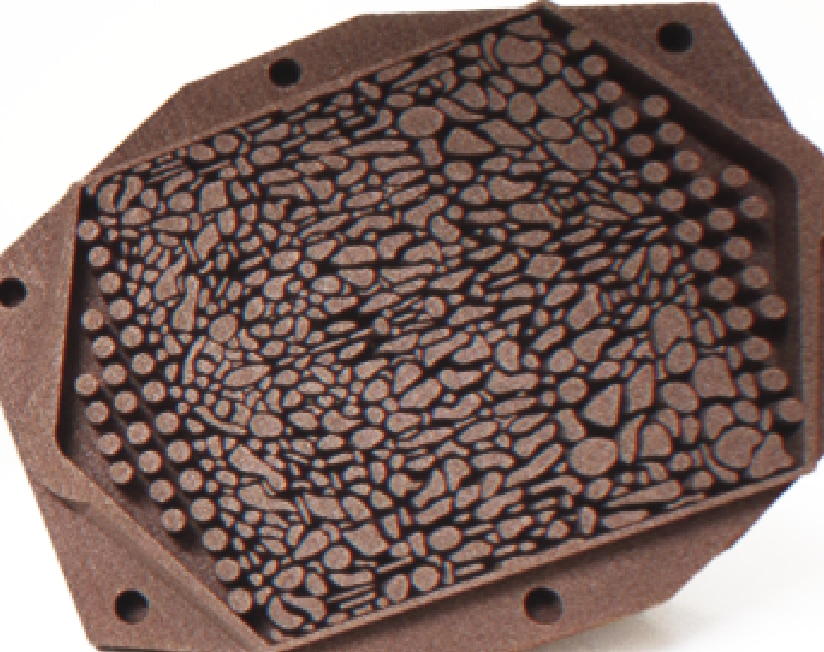

Cold Plate

Heat Exchanger Application

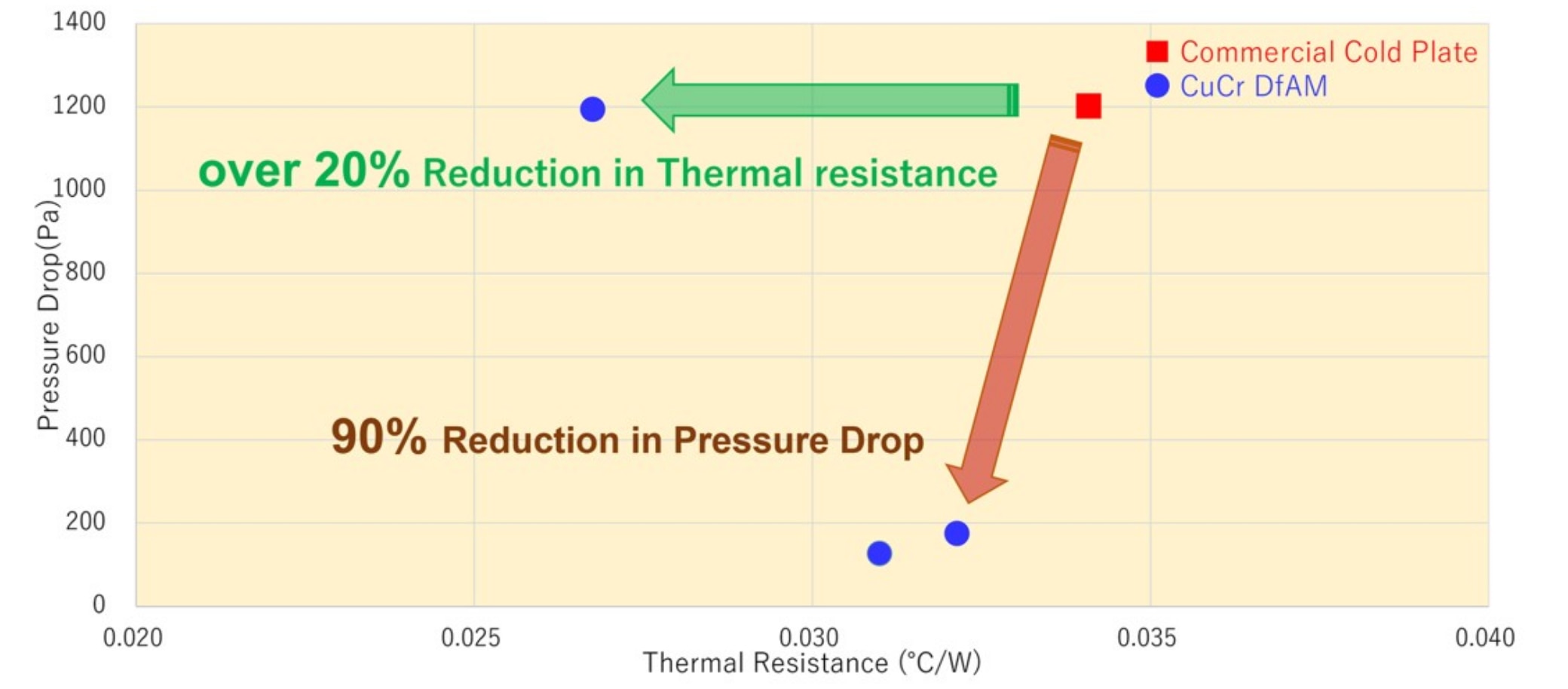

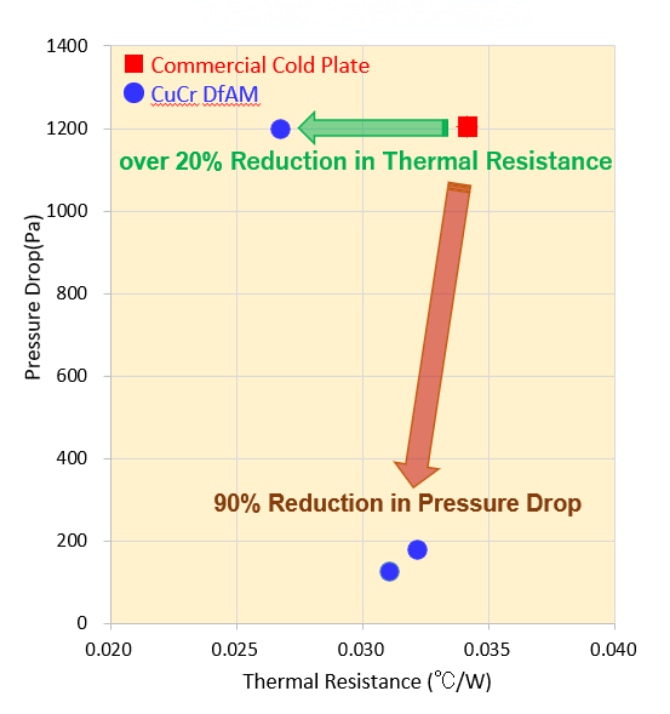

DfAM Cold Plate performance

Design for additive manufacturing (DfAM) CuCr cold plate can reduce pressure drop by 90% and thermal resistance by over 20%

Mitsui's Copper Powder Lineups for Additive Manufacturing

Mitsui is a leading metal powder manufacturer. We provide spherical copper powders made by gas atomize for a variety of 3D printing processes such as Laser Powder Bed Fusion(L-PBF), binder jetting, DLP and cold spray. Please contact us for details.

|

Material |

Material |

AM

Process |

Particle Size (µm) ※ |

Advantage |

Example Applications |

||||

|

D10 |

D50 | D90 |

Cold Plate |

Induction Coil |

Aerospace |

||||

|

CuCr |

MA-CCR25L |

L-PBF |

13 | 30 | 51 | High Conductivity High Resolution Consistent Quality |

✓✓ |

✓ | |

|

CuCr |

MA-CCR25H |

L-PBF |

17 | 32 | 53 | High Strength High Resolution Consistent Quality |

✓✓ |

✓ | ✓ |

| Cu | MA-HC-LOP | L-PBF,

Cold Spray |

16 | 28 | 45 |

High Purity |

✓ | ✓ | |

| Cu | MA-HC-3 |

Binder Jetting, |

6 | 15 | 26 | ✓ | |||

※These numbers are measurement example and do not specify the powder characteristics.

✓✓: Highly recommend

✓: Recommend

✓✓: Highly recommend

✓: Recommend