「熱管理」中的可靠執行者

三井金屬,有著 150年歷史的日本領頭標竿的金屬材料製造商。迎合AI時代,推出了一種適用於雷射粉床熔融(L-PBF)的創新解決方案——銅鉻合金。三井的3D列印銅的解決方案在「熱管理」方面是一個突破性進展,旨在提供卓越的冷卻性能。它不僅能確保穩定的操作環境,還能降低能耗,從而帶來顯著的成本節省。

滿足700W以上的AI伺服器散熱需求

三井金屬的3D列印銅是專門針對高負荷AI伺服器水冷應用的解決方案。能列印150μm以下的超精密設計的能力可以製造出最符合AI伺服器的冷水板,以滿足700至800W以上散熱瓦數需求。

Comparison Chart for Thermal Management Applications

| Material | Company | Laser Output | Relative Density | Conductivity | Resolution | ||

| Thermal Conductivity |

Electrical Conductivity |

Minimal Wall thickness |

|||||

| W | % | W/m・K | % IACS | μm | |||

| MA-CCR25L CuCr |

Mitsui Kinzoku | 400 | 99.5 | 377 | 95 | 200※2 | |

| MA-CCR25H2 CuCr |

Mitsui Kinzoku | 400 | 99.5 | 349 | 93 | below 150※2 | |

| CuCrZr | EOS※1 | 1000 | 99 | - | 80-85 | - | |

| 3T※1 | - | 99 | 300< | 80-90 | - | ||

| Pure Copper | EOS※1 | 400 | 95 | - | 90 | - | |

| EOS※1 | 1000 | 99.6 | - | 100.7 | 700 | ||

※1 Each Company’s website

※2 Mitsui’s internal test result with EOS M290

※2 Mitsui’s internal test result with EOS M290

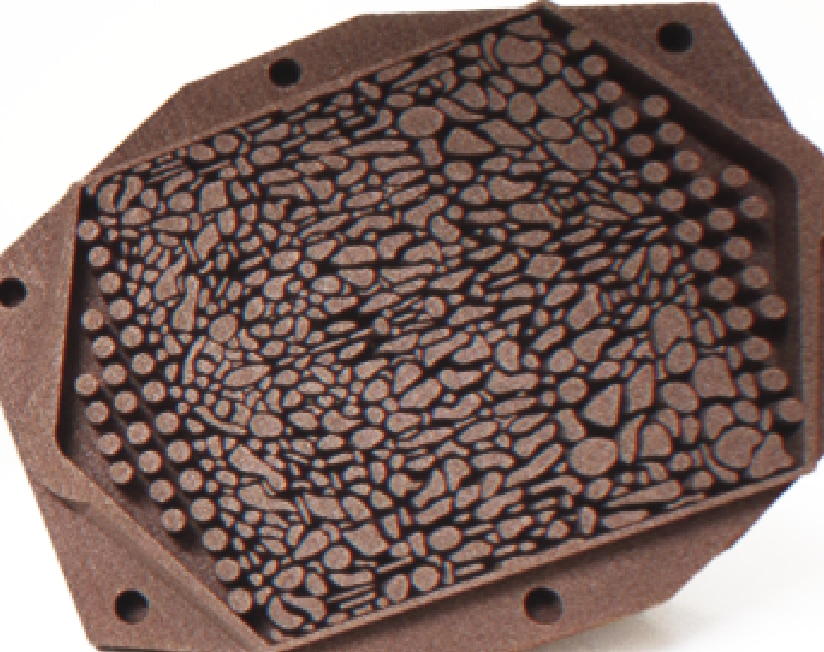

Cold Plate

Heat Exchanger Application

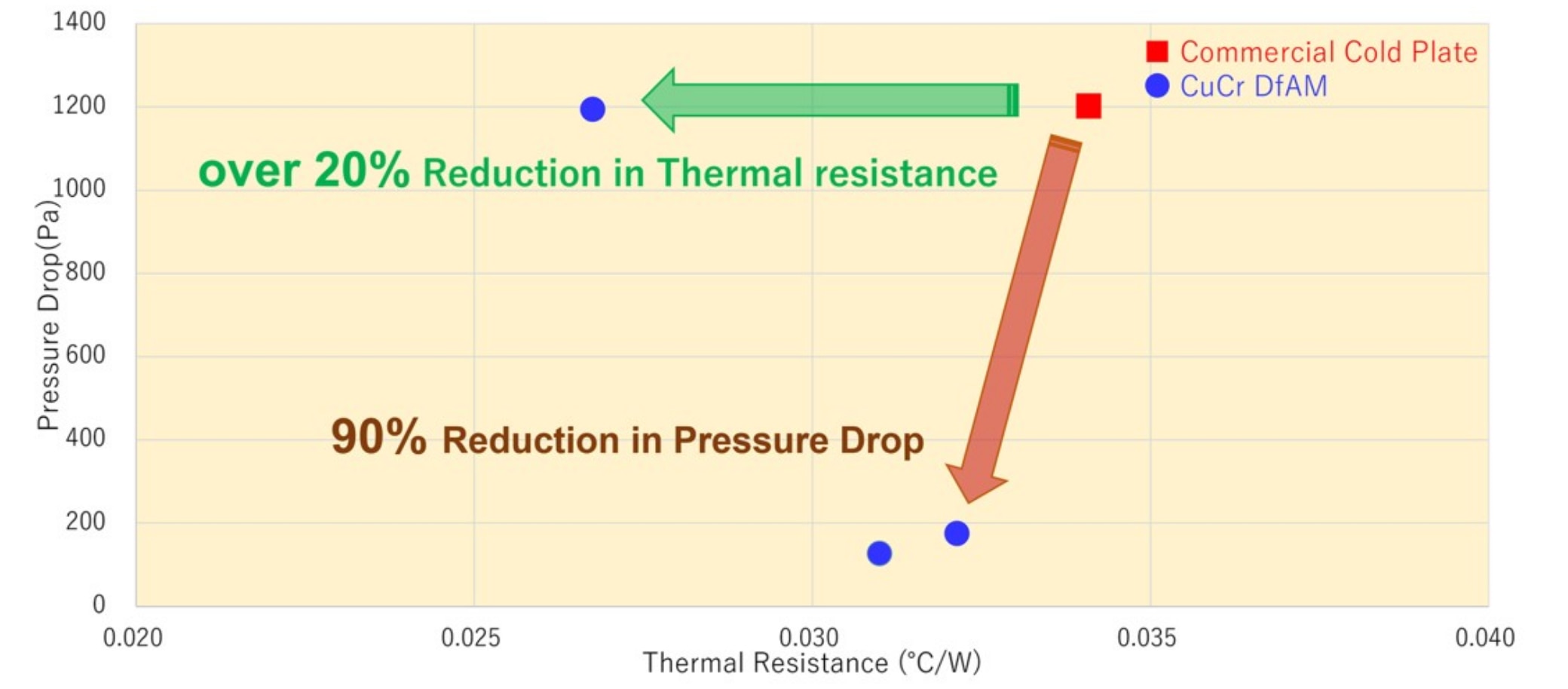

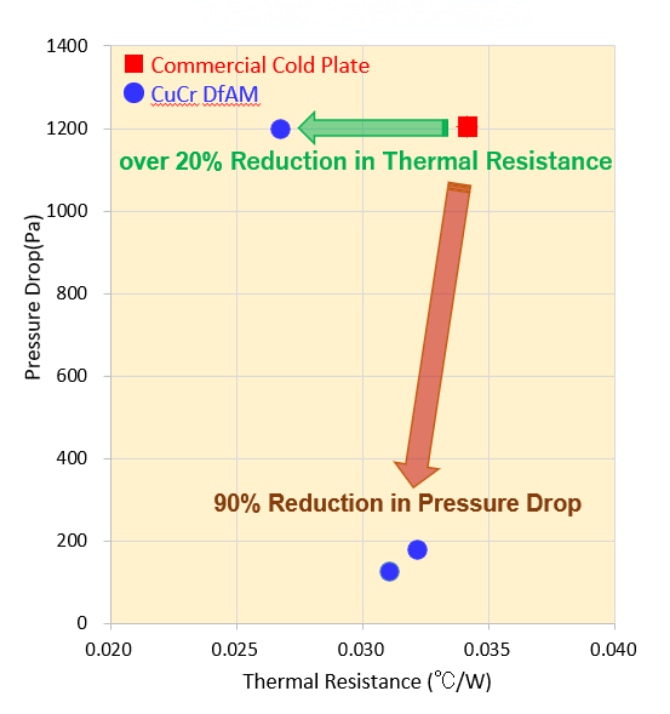

Cold Plate Performance

DfAM CuCr can reduce pressure drop by 90% and thermal resistance by over 20%

Mitsui's Copper Powder Lineups for Additive Manufacturing

We provide spherical copper powders made by gas atomize for a variety of processes such as L-PBF, binder jetting, DLP and cold spray. Please contact us for details.

|

Material |

Material |

AM

Process |

Particle Size (µm) ※ |

Advantage |

Example Applications |

||||

|

D10 |

D50 | D90 |

Cold Plate |

Induction Coil |

Aerospace |

||||

|

CuCr |

MA-CCR25L |

L-PBF |

13 | 30 | 51 | High Conductivity High Resolution Consistent Quality |

✓✓ |

✓ | |

|

CuCr |

MA-CCR25H |

L-PBF |

17 | 32 | 53 | High Strength High Resolution Consistent Quality |

✓✓ |

✓ | ✓ |

| Cu | MA-HC-LOP | L-PBF,

Cold Spray |

16 | 28 | 45 |

High Purity |

✓ | ✓ | |

| Cu | MA-HC-3 |

Binder Jetting, |

6 | 15 | 26 | ✓ | |||

※These numbers are measurement example and do not specify the powder characteristics.

✓✓: Highly recommend

✓: Recommend

✓✓: Highly recommend

✓: Recommend